Micro friction stir welding

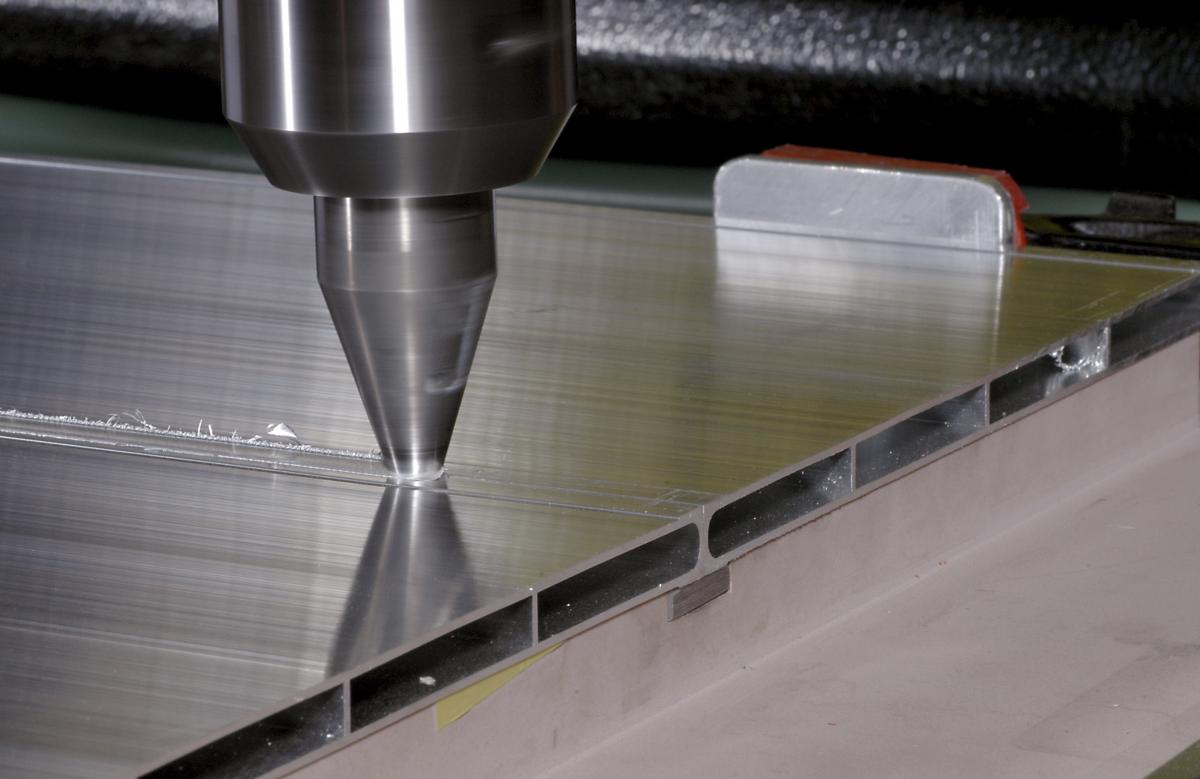

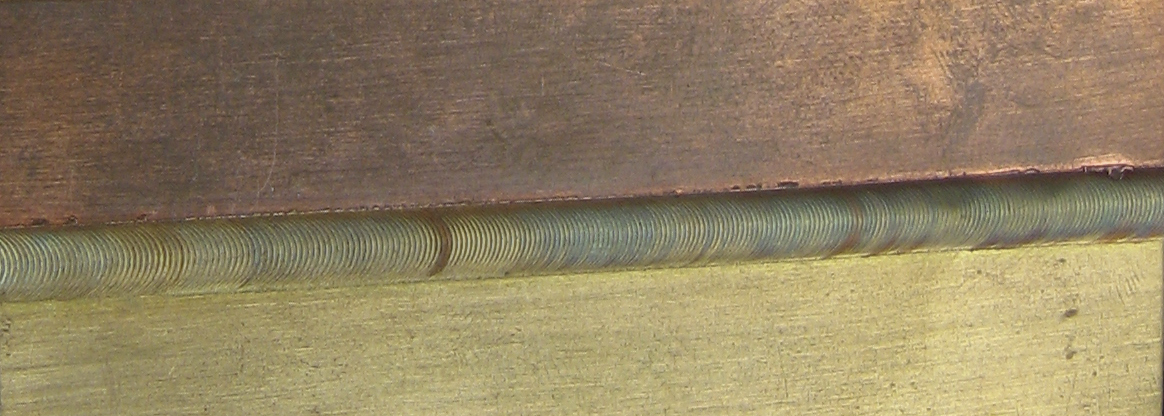

The connection is created thanks to a rotary tool, consisting of a pin with a special profile and a shoulder. The material is heated by friction to a temperature at which the material is in the plastic state. FSW is a welding process where the melting temperature is not reached. This process is particularly suitable for the connection of materials with a low melting point (aluminum, brass, copper, ...). We are speaking of micro-FSW when the thickness is less than 2 mm. In this case, a higher rotation speed and precise positioning of the work pieces is required. The lower limit for the thickness is around 0.3 mm. There are already connections realized of aluminium foils up to 0.3 mm thick.

Joining of an aluminium profile using FSW

Butt joint of foils made of brass and copper, both with a thickness of 0,5 mm