PULSCRIMP: Investigations on magnetic pulse crimping of tubular overlap joints with and without filler material

Electromagnetic pulse joining

High-velocity electromagnetic deformation and welding processes (also know as magnetic pulse forming and welding) are highly innovative automatic production techniques. These processes are based on the same working principle, more specific the use of electromagnetically induced forces to deform, crimp and/or weld workpieces. Most applications involve forming, welding and crimping of tubular workpieces. For more information, the technical annex is referred to.

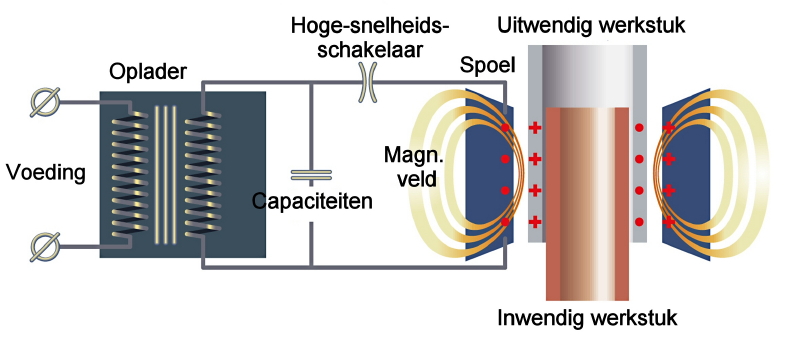

Magnetic pulse crimping and welding is particularly suitable for joining tubular workpieces. The workpieces to be connected need to be positioned in the overlap configuration (one tube shifted over the other). A coil is placed around the overlapping workpieces. A high current is discharged in the coil in a very short period of time (10 up to 30 µs). Due to the magnetic field induced in the coil, eddy currents are generated in the outer tubular workpiece. The magnetic field created by the eddy currents is opposing the magnetic field in the coil. The repelling forces between the two magnetic fields cause the acceleration of the outer workpiece in the direction of the inner workpiece. Depending on the parameter settings and the geometrical configuration and dimensions, either a real weld or a crimp joint is obtained.

Magnetic pulse welding

Magnetic pulse welding shows similarities with explosive welding, however the explosive forces are generated in a safer, controlled manner, by using electromagnetism. The high velocity (300 m/s) and pressure at impact of the outer with the inner workpiece removes the surface contaminations and oxides, which enables a pure metal-to-metal contact between the materials to be joined.

Magnetic pulse forming

In magnetic pulse forming electromagnetic forces are used to deform flat or tubular workpieces according to the shape of a die. Magnetic pulse crimping is similar to forming, but no die is used. An external tubular workpiece can be crimped onto an internal part. The process can be applied to cylindrical, elliptical and square tubular workpieces.

Magnetic pulse forming offers several advantages compared to conventional forming techniques, of which the most important is the improved formability of materials and the reduction of wrinkling and spring-back (no reduction of pre-tension), due to the lower internal stress level. Besides that, the process operates contactless, so no surface indentations occur.

Advantages

The technology offer attractive possibilities for:

- fast and cost-effective joining of non-weldable materials, like heterogeneous joints; since the electromagnetic pulse processes do not use heat to join materials,

- obtaining a larger deformation of some materials, in comparison with conventional forming, while the disadvantages of the conventional processes are avoided,

- creating of complex or new workpieces and products, inaccessible by conventional joining or forming technologies,

- coping with the requirements of environmental compatibility.

Drive axis (Source : PSTproducts)

Part of a gear box (c): TWI

Crimp joints of connectors onto rubber hoses

(c): PSTproducts

Automotive parts manufactured by electromagnetic pulse crimping

(c): PSTproducts

Crimp joints of connectors onto electric cables

Project goals

In order to increase the applicability of the electromagnetic pulse process, further theoretical and application-oriented research was required. By considering the magnetic pulse crimping process as an alternative to magnetic pulse welding, the process applicability can be increased enormously, on the condition that the shortcomings of the crimping process can be resolved (not being gas-tight of the crimp joints).

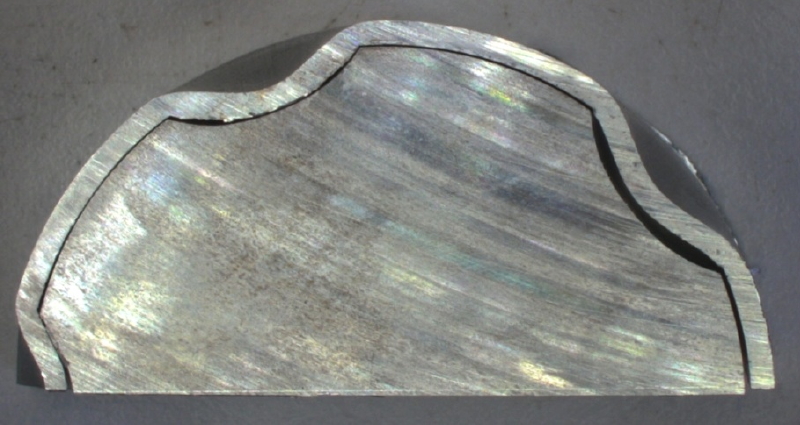

The applicability of magnetic pulse crimping was studied, and besides that, a new process variant was developed: magnetic pulse crimping with addition of a filler material.

The project goals can be described as follows:

- Demonstration that magnetic pulse crimping is a valuable process for realising strong axial and torque joints (without addition of a filler material).

- Development of a new process variant in order to create gas-tight crimp connections.

- Knowledge about the properties of the joined materials and workpieces (strength, ductility, microstructure, spring-back, ...) and concerning the applicability (where to implement and at which cost).

- Enabling companies to manufacture new or complex products, previously not possible (e.g. joining of non-weldable materials, obtaining larger deformations, …).

Project description

Methodology

The methodology can be summarised as follows:

- Acquisition of know-how on the magnetic pulse crimping process with and without filler materials.

- Investigation of appropriate quality control methods, best suited for this new technology (destructive and non-destructive examination).

- Investigation of the joint characteristics for potential industrial applications and demonstration workpieces.

- Study of the various factors involved to achieve the desired joint properties of the axial and torque joints (resistance, ductility, ...), as well experimentally as with finite-element modelling,

- Investigation of the correlation between the joint characteristics and the process parameters.

- Technical-economical evaluation of the use of the process for industrial applications, compared to other conventional welding processes.

- Transfer of the obtained laboratory results to the industry, and stimulation of the use of the new techniques,

This project provided objective technical-scientific, as well as practical and economic knowledge in order to make it possible for individual companies to make a technically and economically justified decision on whether or not to implement this technology in their production, and which variant to choose (without filler material or the new variant).

European collaboration

The project results were achieved by a close cooperation between the project consortium partners, each with a specific and necessary task to fulfil:

- The experimental research was performed by BWI and SLV, both possessing magnetic pulse equipment.

- The execution of the experimental work was assisted by finite-element modelling of the process, performed by OCAS.

- IFF investigated suitable filler materials to be used in the new variant.

- Where-ever needed, assistance was provided by equipment suppliers. This was the case for coil development and manufacturing, field shaper optimisation, modelling assistance, …

Target group

The Flanders and German regions have a large number of metal processing companies, and due to the increasing international competition from low wage countries, they are constantly forced to decrease production costs in order to remain competitive. The target group has clearly a need for fast, innovative and more cost-effective production processes. Otherwise they will be obliged to move the production process to countries with lower labour costs, with loss of jobs and knowledge as a result.

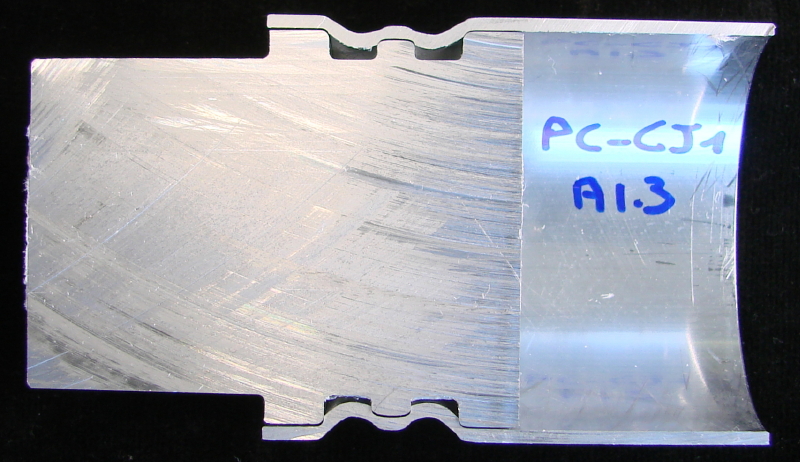

Axial crimp joints in aluminium

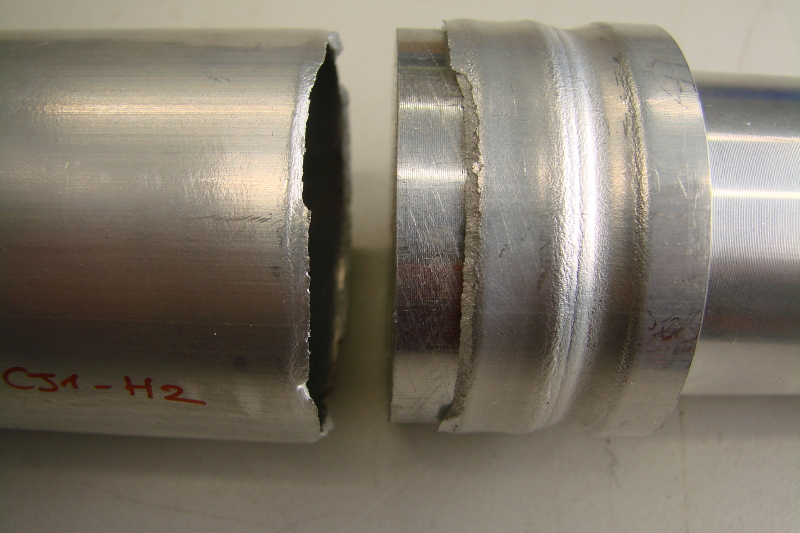

Torque crimp joints