ACODEPT: Advanced Coil Design for Electromagnetic Pulse Technology

Electromagnetic pulse technology

The electromagnetic pulse technology is based on the utilisation of current driven electromagnetic forces (Lorentz forces) acting on the workpiece. The force application is contact free and no working media or lubrication is required, so that any disturbance of the surface due to wear is avoided and the cleaning effort during production is minimized.

In principle, three major process variants are differentiated :

- Electromagnetic compression of tubes or hollow profiles by a typically cylindrical coil surrounding the workpiece,

- Electromagnetic expansion of tubes or hollow profiles by a typically cylindrical coil positioned inside the workpiece, and

- Electromagnetic forming of flat of three-dimensionally preformed sheets by an accordingly shaped coil

Electromagnetic forming technologies offer attractive possibilities for

- obtaining increased formability for numerous materials, in comparison to conventional forming, while avoiding some important disadvantages of the conventional processes,

- fast and cost-effective joining of conventionally non-weldable materials, like heterogeneous joints;

- creating complex or new workpieces and products, not feasible by conventional technologies,

- improving the working conditions of the welder or operator, since the EMF technology is environmentally clean (no heat, lubricant, fumes, shielding gases, radiation, ...).

Coils

Critical components of the technology are the coils, which are mostly application-specifically designed. When inappropriately designed or constructed, coil lifetime is very limited and/or low process efficiency is obtained. Durable, robust and efficient coil systems are however essential for a successful implementation of EMF in industry.

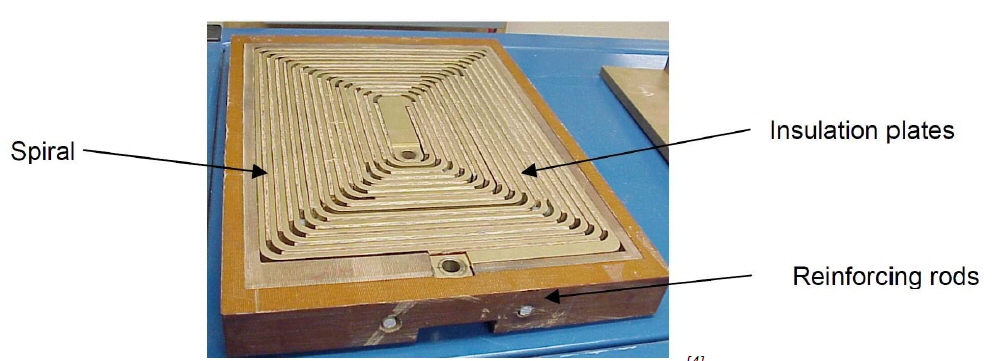

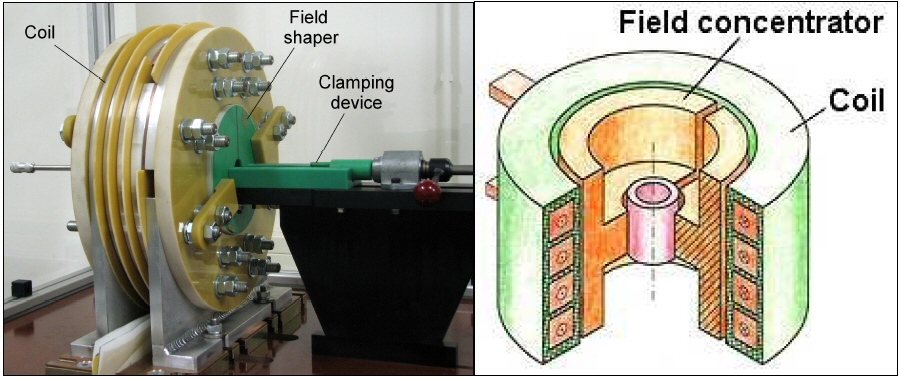

Flat coil

Circular coil

Design of coils

Robust and efficient coils which can resist magnetic fields above 20 T have been problematic. Moreover, robust coils, able to withstand the process forces and temperature cycles, possess usually a low efficiency. Up to now only very little independent application-oriented research has been carried out regarding the design and construction of EMPT coils for industrial applications.

Project goals

The overall aim of the ACODEPT project is enabling companies to produce faster and more efficiently by implementing electromagnetic forming, welding, and cutting processes. As a prerequisite for this, the companies shall be provided with design strategies for durable, robust and flexible tool coils for specific applications.

To reach this goal the following technical targets are aimed at in this project:

- Reviewing the current state of the art and gathering the information related to coil design,

- Developing finite-element models, which will increase the knowledge about the process and which will serve as a tool in the coil design process,

- Developing methodologies for designing coils for forming and cutting of sheets and forming and welding of tubular workpieces,

- Providing guidelines for manufacturing, material selection, insulation strategy and other construction-related aspects,

- Manufacturing and testing of coil prototypes, for the development of industrial applications, and

- Providing the manufacturing industry with all essential information to make a considered decision about the successful integration of the EMPT-process in their production.

Project description

Partners

The experimental investigations will be performed by the Belgian Welding Institute (BWI) and Fraunhofer (IWU), both having an electromagnetic pulse equipment at their disposal. EELAB of the Ghent University will use its expertise for the calculation of the magnetic forces and currents for the determination of the desired shape of the coil system. Finite-element modelling is done by the Technical University of Chemnitz(TUC). The project is coordinated by EFB; the European Association of Sheet Metal Working.

More information

- Project website

- Summary of project results

- More information about the electromagnetic pulse technology