CORONA: Post-treatment techniques for stainless steels

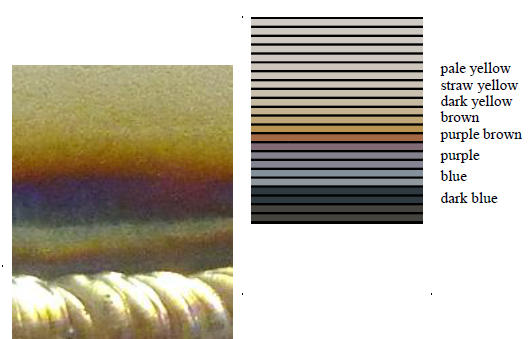

Stainless steel of different grades (for example, 304 and 316L) is used to a large extent in chemical companies in view of the good corrosion resistance that these materials offer. However, when stainless steel is welded, this material is heated locally at high temperatures. The heat affected zone that is located next to the weld, experiences temperatures higher than 1000° C. If oxygen is present, it will immediately react with the metal. This creates what is commonly referred to as "heat tints".

Heat tints on stainless steel 316.

Research has shown that heat tints can drastically reduce the corrosion resistance. It is therefore recommended that the heat tints be removed. Until now, the best method is pickling with aggressive chemicals such as hydrogen fluoride (HF; also referred to as hydrofluoric acid) and nitric acid (HNO3). After the treatment with these chemical products, the corrosion resistance is equivalent to the one of the base material.

For both installation companies and users of such systems, the use of HF and HNO3 however represents health and safety risks.

Different alternative post-treatment techniques are however available on the market such as, for example, electrothermal pickling with citric acid or phosphoric acid, laser cleaning or mechanical cleaning. There is insufficient (independent) information about these techniques regarding the improvement of the corrosion resistance of the welded area after the treatment.

Project goals

The objective is to arrive at a ranking of the most suitable cleaning techniques for specific applications.

Importance of this research for metal machining (welding) companies

- Depending on the application, the best post-treatment can be selected > optimisation of resources

- Work procedures can be adjusted if fewer hazardous chemicals need to be used after welding > reducing health and safety risks.

Importance of this research for chemical companies

- Alternative post-treatment techniques can be accepted when specifying the welding work > reducing health and safety risks.

- If cleaning does not represent a significant added value for some less corrosive conditions > avoid the cleaning step.

Results

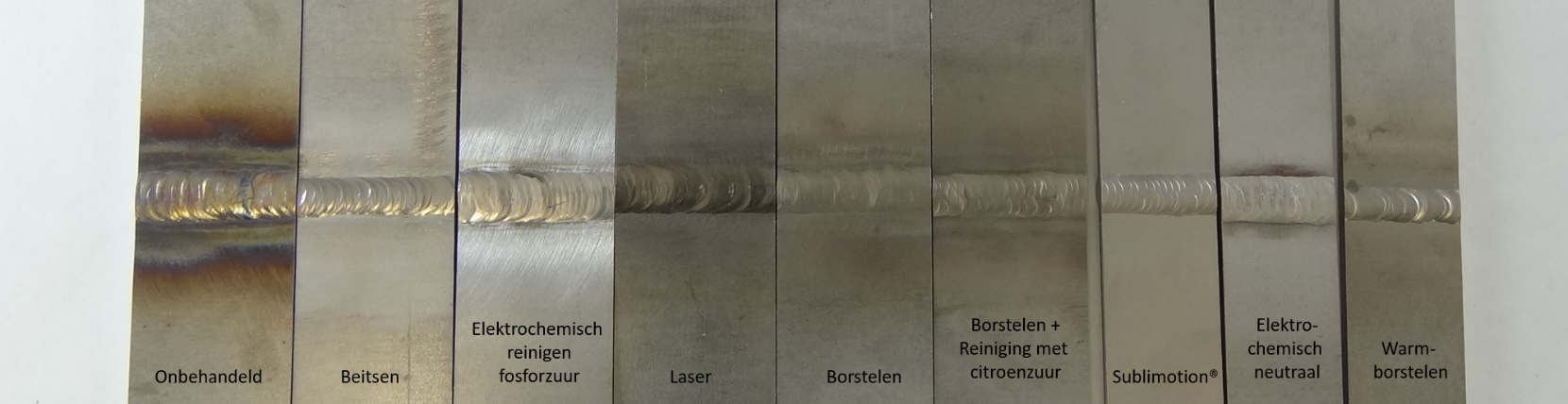

The selected treatments included:

- No cleaning (for reference)

- Pickling with paste (product with HNO3 and HF)

- Electrochemical cleaning with phosphoric acid

- Electrochemical cleaning with neutral solution

- Laser cleaning

- Brushing after cooling the stainless steel

- Brushing during cooling, at a temperature of 40-50 ° C ("warm brushing")

- Specific surface conditioning technique (Sublimotion®)

Examples of test samples after treatment are shown in the figure below.

Examples of test samples after treatment

Several short corrosion tests are being tested, including salt spray test and pitting corrosion test. In addition to short corrosion tests, long-term tests are also carried out in various atmospheric corrosion categories and in various liquids (demineralized water, city water and artificial sea water).

Workshops and demonstrations will be organized in the coming period. More information will be made available shortly.

CORONA is an intercluster project between SIM and Catalisti and is supported by the Flemish Government.