Electron beam welding

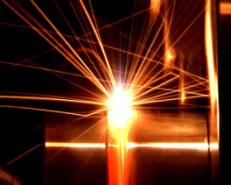

This welding technology is included in the category of "beam welding". The energy for welding is added to the workpiece because a bundle of electrons is released, focused and accelerated to about half of the speed of light (150.000 km/s) and focused on the workpiece. In case of sufficient energy, the materials will melt locally and even partly evaporate.

Because a beam of electrons is scattered quickly in gas, this process is almost always performed in vacuum. Welding under vacuum has the important advantage that no oxidation occurs or no interaction with oxygen or hydrogen can take place. This is ideal for welding materials that oxidise very quickly, such as tungsten, titanium, molybdenum, zirconium, which are used in e.g. the aircraft and space industry.

Applications

The automotive sector is also interested in this technique: minimal distortion is a big advantage for series production of gears of the gearbox. Electronic components will also be welded with electron beam welding, due to the high precision and low heat input, making the electronics remains protected. On a few millimeters away from the weld, there is no thermal influence. With this technique, it is also possible to weld dissimilar materials.

Benefits

- Low energy consumption

- High reproducibility due to the high degree of automation

- Excellent weld quality due to the minimal heat input and deformation

- Thin weld seams with narrow HAZ (less than 10:1)

- Weld depth of more than 100 mm is possible

- High welding speed up to 250 mm/s

- Cost advantage for processing of thick-walled parts

Feasibility study

BWI can assess the feasibility of this process for your materials or applications. Through our partner network, we can also carry out welding trials with subsequent full weld characterisation. For further questions, please contact Wim Verlinde.