Fatigue resistance

Fatigue testing

Fatigue is one of the most common causes of failure of machine components or constructions, in addition to corrosion. Usually, this is a perfectly normal type of wear. However, with a bad design or a low weld quality, welds can fail within the expected life span.

BWI performs fatigue tests on welded components.

- Click here for an overview of the tests that we can perform.

Fatigue resistance of high strength steels

BWI investigates methods to improve the fatigue resistance of high strength steels. In many applications, components with welded joints are also heavily loaded in fatigue. Many investigations indicate however that welded joints in high strength steels do not perform much better in fatigue, compared to joints in plain carbon steels. As a result, the high strength steels lose a part of their usefulness.

There are however several possibilities for increasing the fatigue resistance of welded joints in high strength steels, for example by applying a special treatment, such as remelting of the weld by plasma or TIG welding. Another possibility is the use of hammering (e.g. PIT; Pneumatic Impact Treatment). Most of these possibilities are described in literature, but the application in industry in Flanders is still limited, especially because there is no specific practical knowledge available and because there is no data in literature on the latest steel types.

BWI can support companies through advice on the most suitable techniques and by well-substantiated guidelines.

The applications can be found in mechanical engineering (for example in Figure 1) and bridge construction (Figure 2). The goal is to increase the employability of high strength steels.

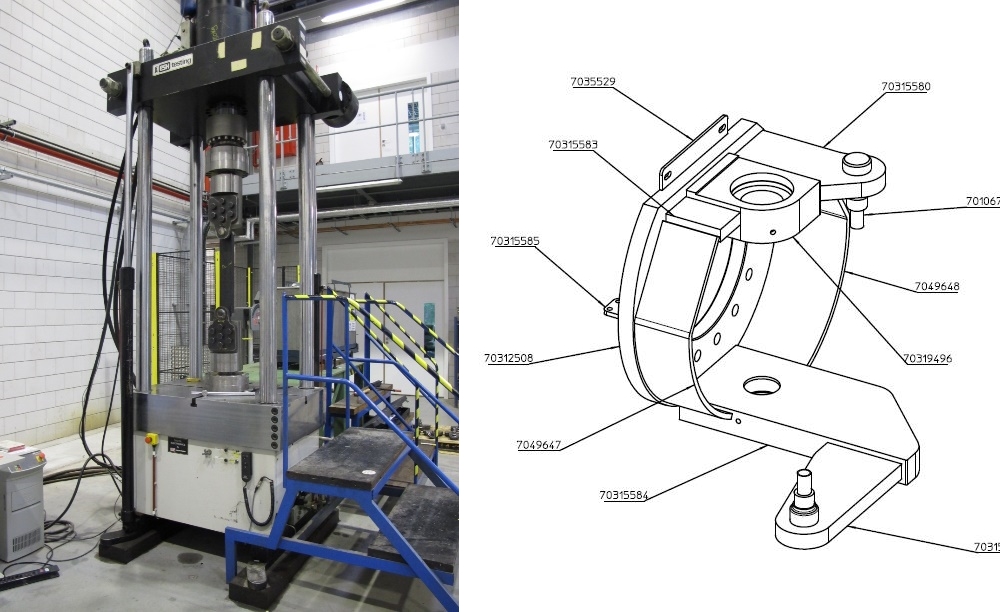

Figure 1: Fatigue tests on heavily loaded welded joints in the steering mechanism of an agricultural machine

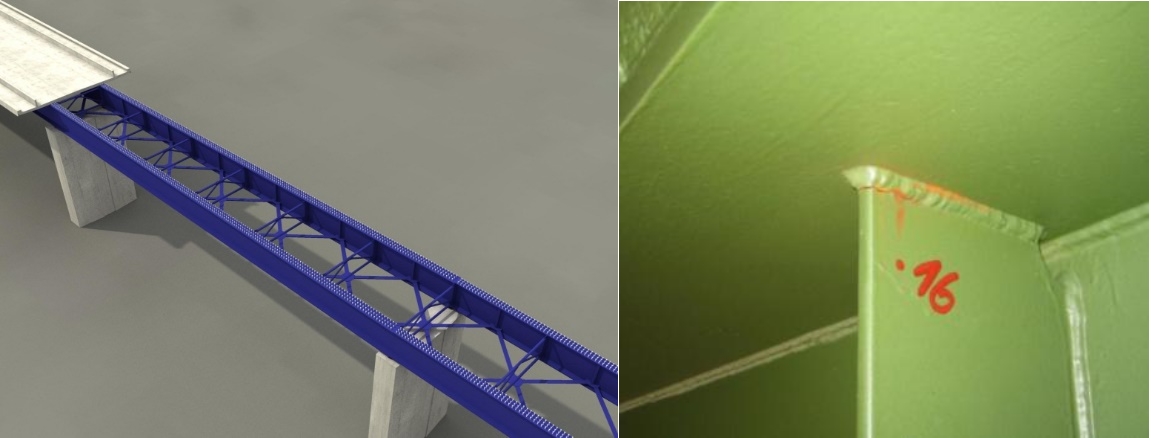

Figure 2: Welded transverse stiffener in a motorway bridge: this weld detail is sensitive to fatigue cracking and buckling

Design and implementation

BWI provides advice on the design of welded constructions, with attention to the sensitive weld details. This is a first step to increase the fatigue life of welded constructions. In addition, the required weld quality has to be determined and the corresponding quality controls.

Corrosion fatigue

Corrosion fatigue is a fatigue phenomenon which is influenced by aggressive environments. The latter may consist of an electrolyte solution or a gas environment. Factors that may severely affect the corrosion fatigue behaviour are of course the changing loads, but also the load frequency, the nature of the environment and the material properties.

Because many constructions are exposed to changing loads in aggressive environments during their lifetime, it is important to determine how these structures behave under these conditions.