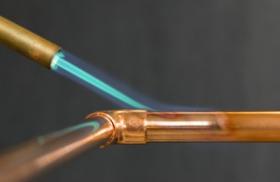

Soldering / Brazing

The connection is made through melting of the solder and to let it flow in between the parts. Oxidation occurs when soldering; therefore a reducing flux is used. The solder may have all sorts of shapes, such as a rod, wire, grain, powder or paste.

Soft brazing occurs at relatively low temperature (< 450 °C), with the solder alloys based on tin, copper and silver.

Brazing is done at a temperature above 450 °C.

Feasibility study

BWI can assess the feasibility of this process for your materials or applications. Through our partner network, we can also carry out welding trials with subsequent full weld characterisation. For further questions, please contact Wim Verlinde.