Friction welding

Principle

In friction welding, heat is produced by rubbing components together under load. Once the required temperature and material deformation is reached, the action is terminated and the load is maintained or increased to create a solid phase bond. Friction is ideal for welding dissimilar metals with very different melting temperatures and physical properties.

The action of rubbing two objects together causing friction to provide heat is one dating back many centuries. The principles of this method now form the basis of many traditional and novel friction welding, surfacing and processing techniques.

The friction process is an efficient and controllable method of plasticising a specific area on a material, and thus removing contaminants in preparation for welding, processing, surfacing/cladding or extrusion. The process is environmentally friendly as it does not require consumables (filler wire, flux or gas) and produces no fumes.

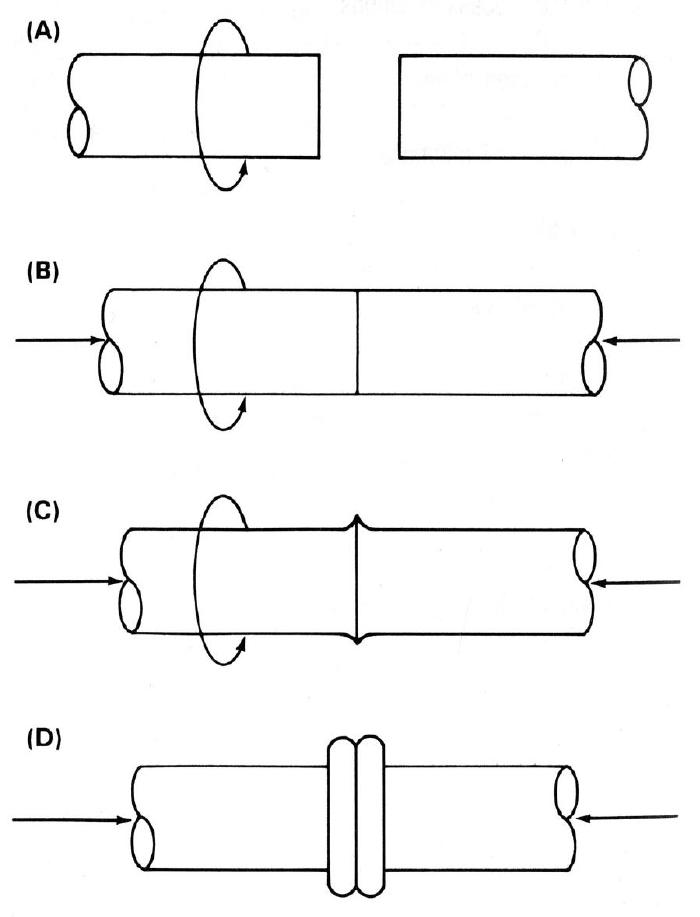

The principle of friction welding in its most simple form is presented in Figure 1. Suppose that two axes or tubes have to be butt-welded, then one part is clamped while the other is rotated and pushed against it. If both parts are in contact with each other under a controlled axial force, the friction forces cause a resisting torque. The resulting mechanical energy is converted into heat in the contact area. The generated heat increases the temperature in a relatively short time to the welding temperature. The rotating part is then disconnected from the drive, decelerated and an axial forge force is exerted to create the weld between both parts. During the heating phase, plastic material is pushed out of the weld zone under the influence of the axial compressive forces, to form the characteristic welding flash (see Figure 2).

Figure 1: Principle of rotary friction welding

Friction-based joining processes

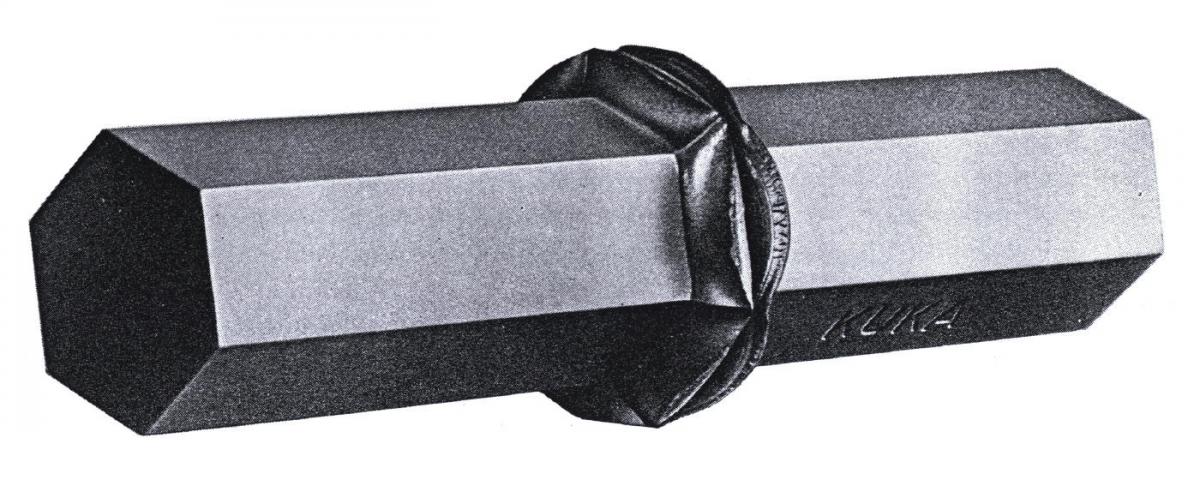

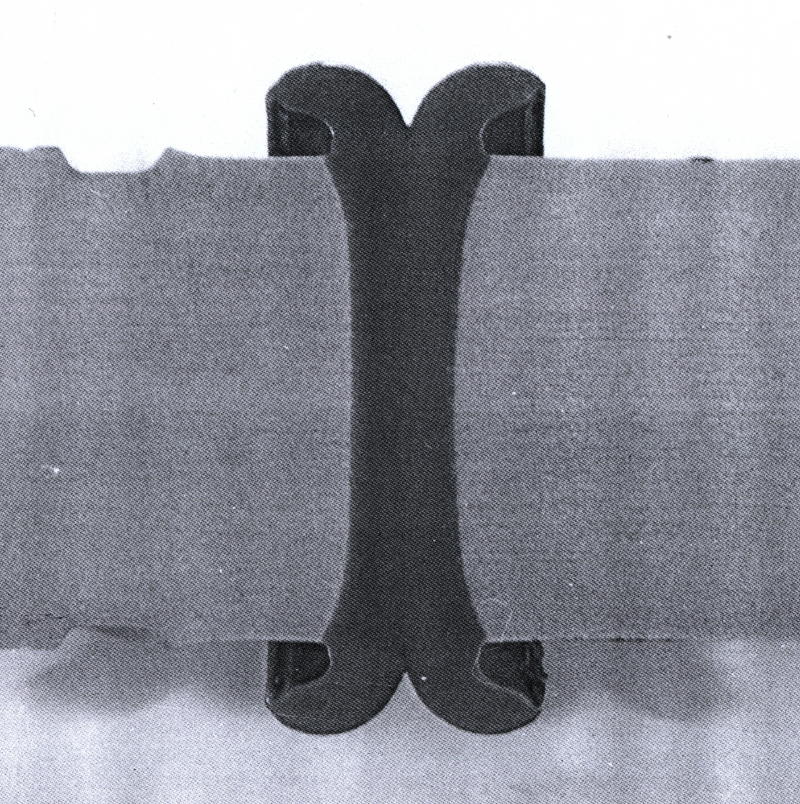

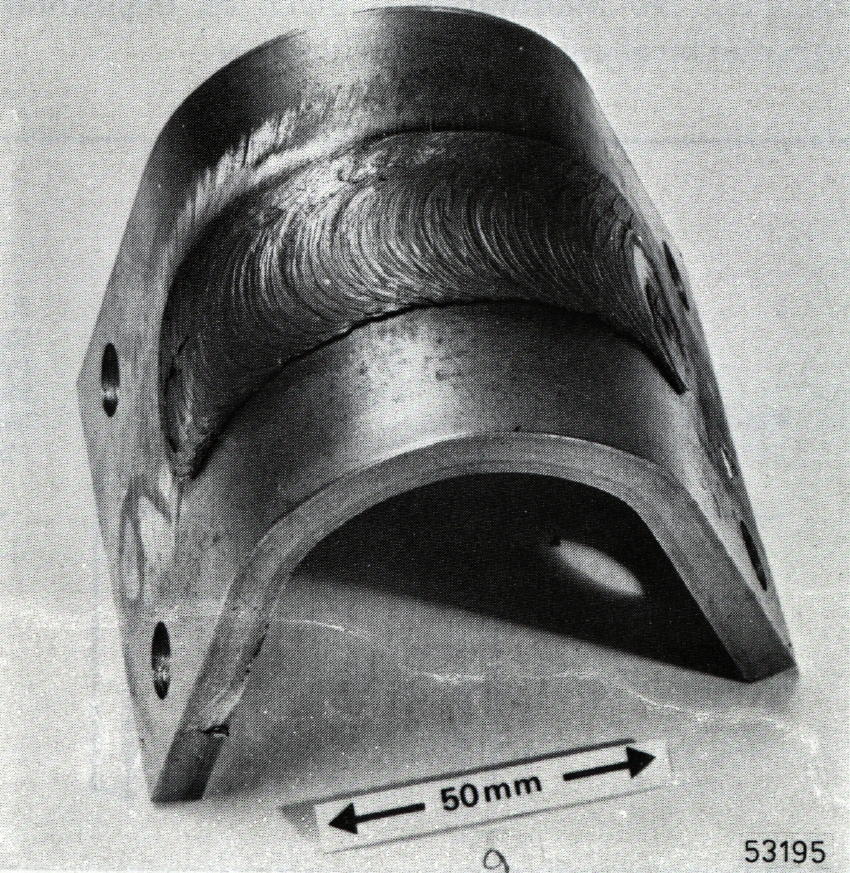

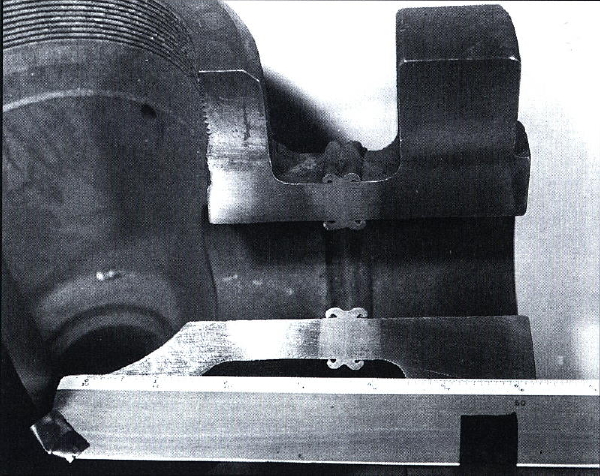

The most widely used variant of the process is the rotational friction welding process. It can be used for connecting rotationally symmetrical workpieces, such as tubes and rods (Figure 2), but also for some more complex geometries, as shown in the figure 3.

Figure 2: Friction welded bars |

|

In addition to the rotational friction welding process, there are a number of other variants. Orbital friction welding can be used for workpieces with a non-rotationally symmetrical cross section welding (see Figure 4). Both workpieces are brought into contact under a controlled pressure and one part performs a small circular motion compared to the other. This provides a uniform tangential speed over the entire surface. If the movement stops, both parts are quickly aligned with each other and the forging force is applied to create the weld.

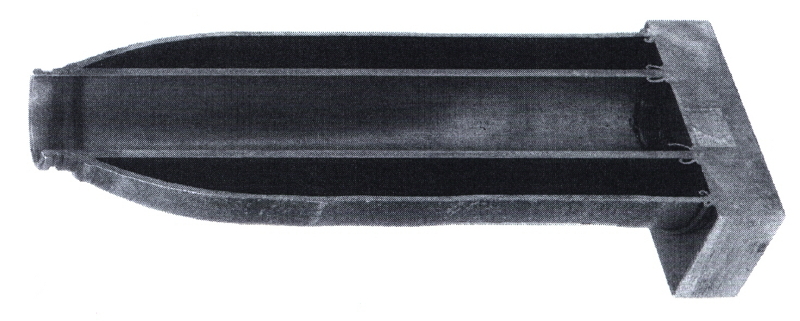

In linear friction welding (Figure 5), the necessary heat is generated by a back-and-forth motion of the workpieces to be welded. This process can also be used for welding of workpieces with a non-rotationally symmetrical cross section.

|

|

Figure 5: Linear friction welding |

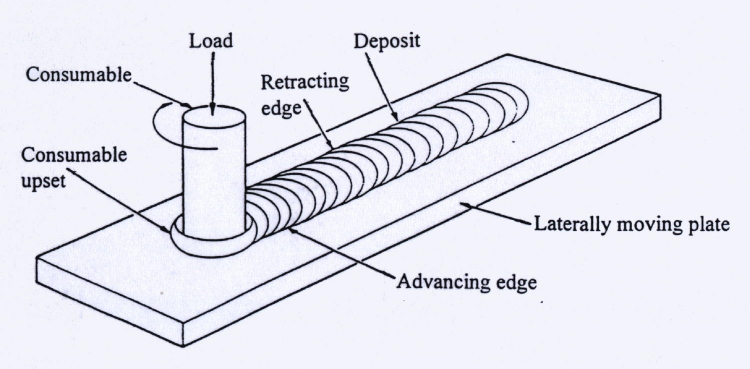

The friction process can also be used for applying clad layers (cladding-see Figure 6) or to perform repairs using the "friction stitch" welding process (Figure 8).

Figure 6: Cladding using the friction surfacing process |

Figure 7: Destructive testing of a clad layer applied by friction surfacing |

Figure 8: Repair welding using the friction stitch process |

Advantages of the friction welding process

- High quality joints, with a favourable metallurgical structure, since the materials don’t melt during the welding operation.

- No special preparation of the workpieces required.

- Little distortion after welding, due to the short welding time and the low maximum temperatures.

- Possibility to connect workpieces with strongly different sections.

- The welding process is much faster than the conventional welding processes.

- Friction welding allows cost savings (process time, material costs).

- Dissimilar materials can be welded; which are impossible to weld with other processes, such as aluminium or copper to steel.

- Very good reproducibility and possibilities for automation.

- Environmentally clean process: no protective gases, welding fumes, radiation or noise

- No need for certified welders

Applications

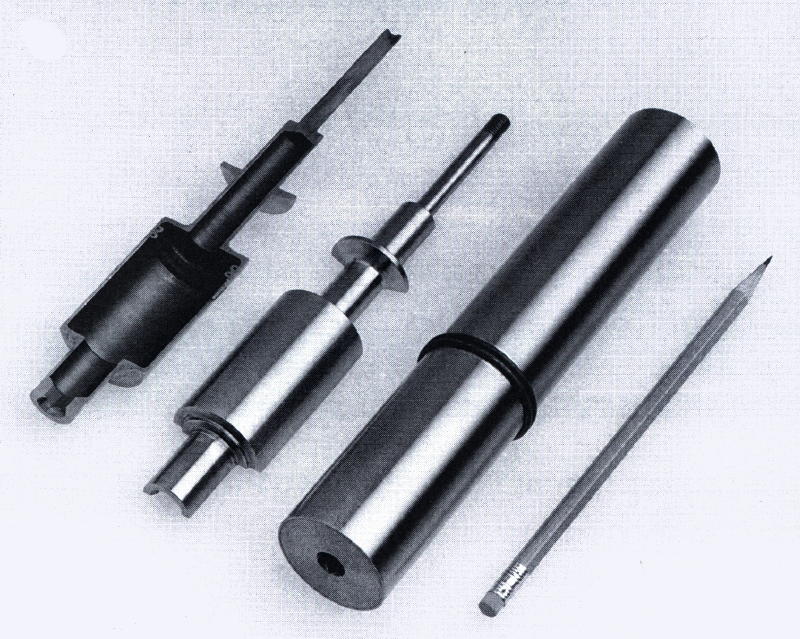

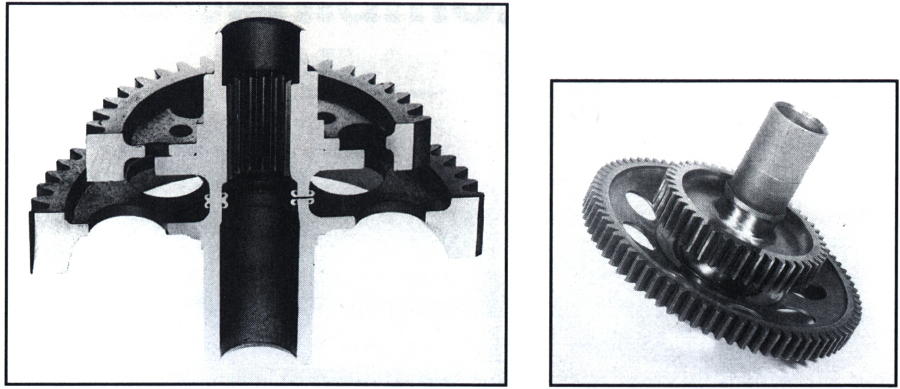

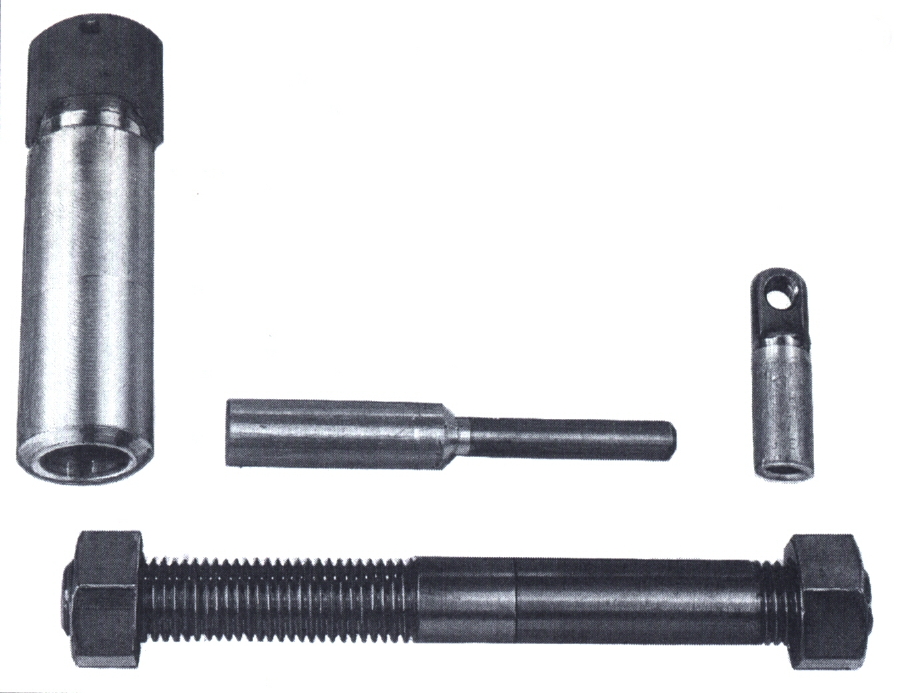

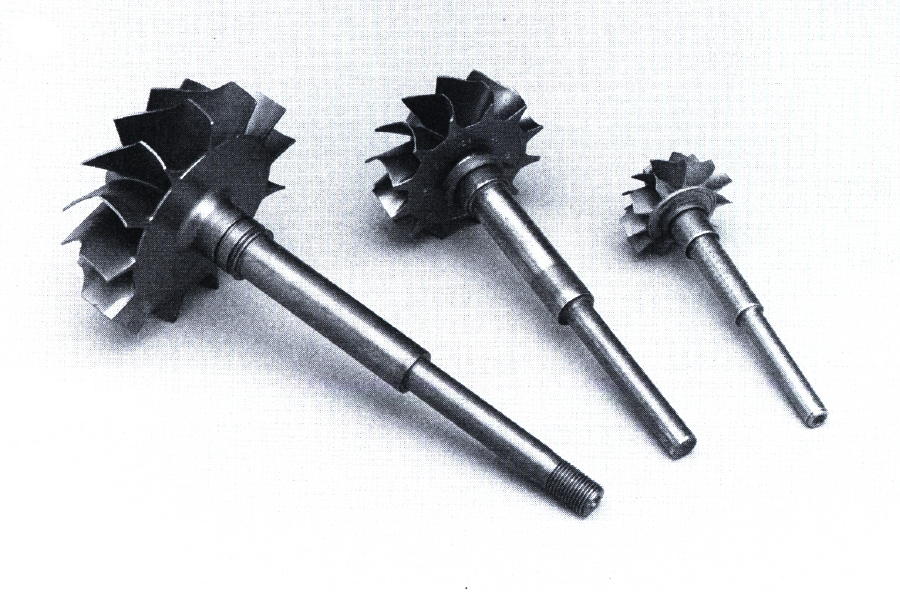

The friction welding process can be used for a variety of applications. It can for example be used in the aerospace industry for welding hook bolts (Figure 9), for the manufacture of lightweight piston rods (Figure 10) or for parts of gearboxes (Figure 11).

Figure 9: Production of hook bolts |

Figure 10: Welding of piston rods |

Figure 11: Welding of gearbox components |

|

Friction welding is also used in the petrochemical industry, for example for welding flanges to the housing of hydraulic valves (Figure 12) or for welding drill pipes. The friction welds are strong enough to resist the high torques during drilling.

Figure 12: Weld of a flange to the housing of a hydraulic valve |

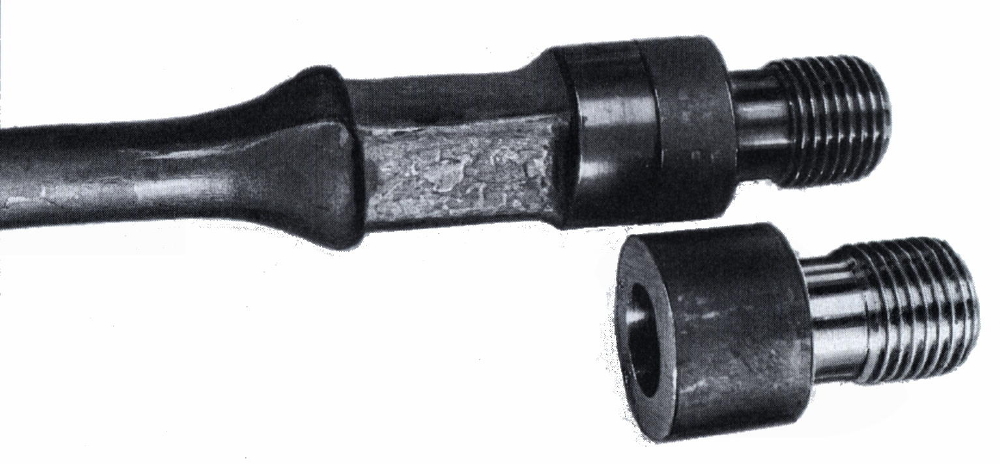

Figure 13: Weld of a forged bar to a connector with screw thread |

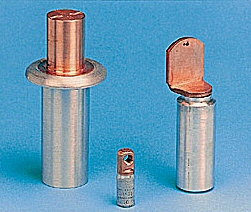

Using friction welding, it is also possible to connect materials which are impossible to join with the conventional welding processes. Examples include aluminium to steel (Figure 14) or titanium to copper. This option allows to save costs, by a smart design of such components. An example of this is the design of a valve of an internal combustion engine (Figure 16). The valve disk in made of a heat resistant material, to be welded to the valve stem made from a wear-resistant material. Other examples of bimetal connections are shown in the figure 17.

Figure 14: Connection of aluminium to steel Figure 14: Connection of aluminium to steel |

|

Figure 16: Weld of a vavle disk to the valve stem |

Figure 17: Examples of dissimilar metal welds : aluminium/copper for electric connectors en titanium/copper threaded bars Figure 17: Examples of dissimilar metal welds : aluminium/copper for electric connectors en titanium/copper threaded bars |

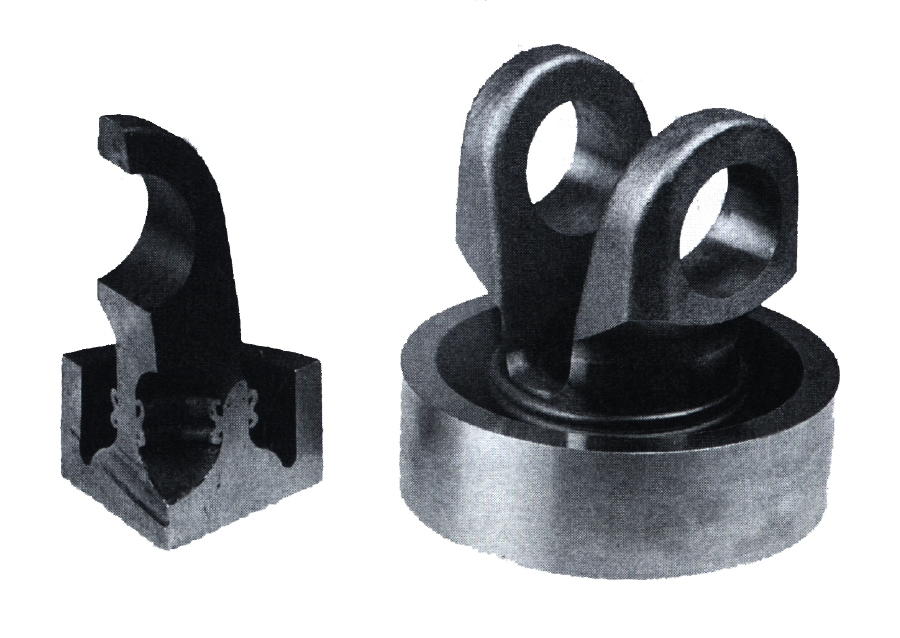

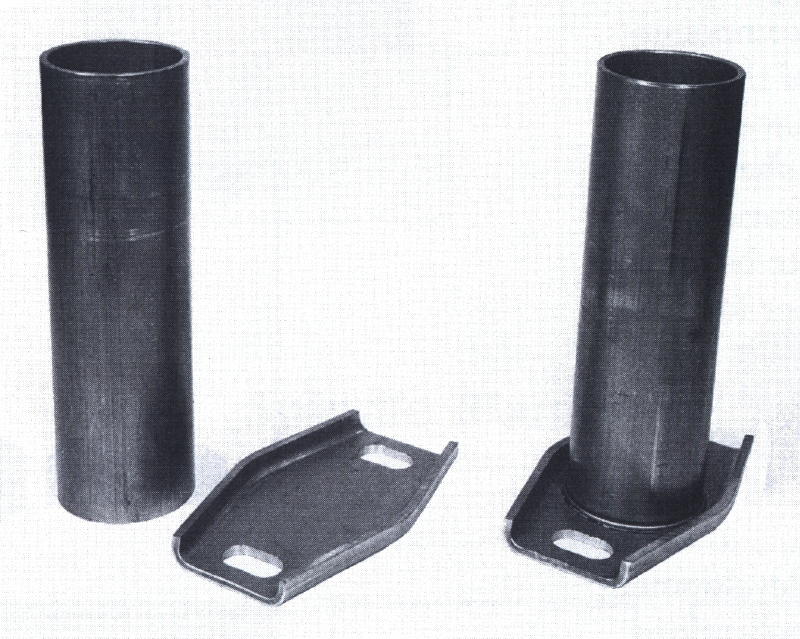

Friction welding is also widely used in the production of spare parts for trucks and agricultural vehicles (figures 18 and 19). Substantial cost savings can be achieved by replacing fully forged pieces by smaller forgings welded to rods or tubes.

Figure 18: Piston of a diesel engine |

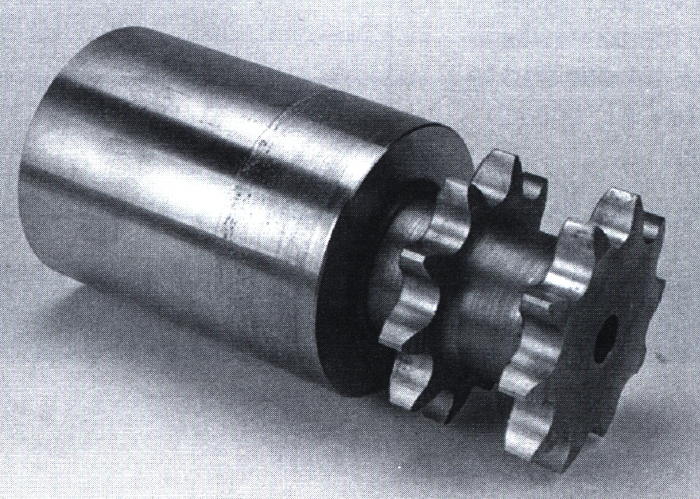

Figure 19: Chain wheel welded to a bar |

Friction welding is used for the production of parts in the automotive industry, such as stabilizers, valves, drive rods, steering columns, water pumps, …

Figure 20: Turbo components Figure 20: Turbo components |

Figure 21: Gearbox component |

Figure 22: Part of a shock absorber |

|

Research

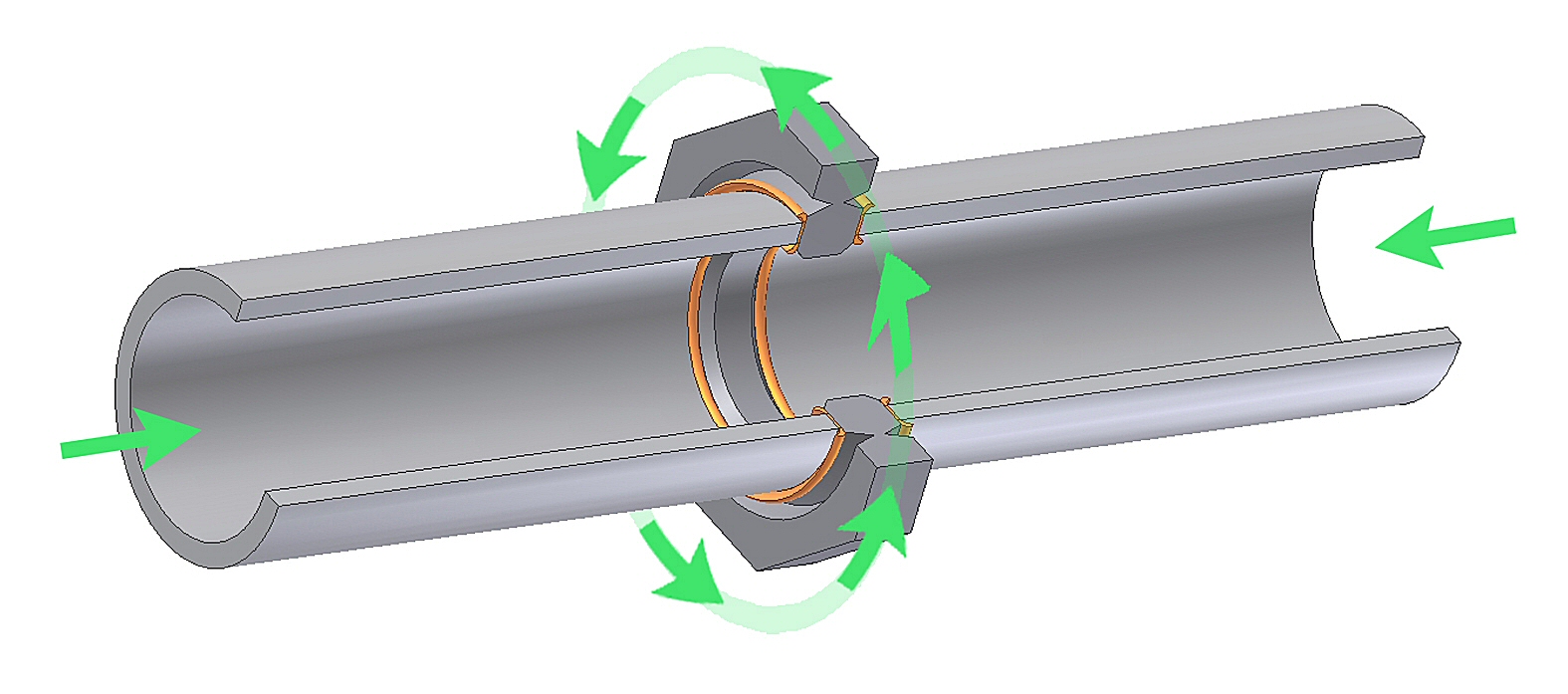

The Belgian welding Institute has many years of experience with the friction-based joining processes. In the past, the conventional rotational friction welding process was examined in detail, for example for the development of an innovative welding process for welding pipelines. A new variant of the friction welding process was developed, namely the friction welding with a rotating between ring (Figure 24). BWI also possesses a friction welding machine with a drive power of 160 kW.

Figure 24: Friction weld of 2 pipes using a rotating intermediate ring

Contract research

For confidential investigations for the specific needs of a particular company, BWI can perform contract research commissioned by the industry.

Because of the ever-increasing competition in the sector, we are convinced of the necessity of replacing labour-intensive welding processes by automated innovative welding processes. Friction welding is well suited for this purpose:

- it is an automatic process, in which the quality is independent of the operator, which is very important since the quality requirements become more and more stringent, which are sometimes difficult to achieve with manual welding processes.

- There is a shortage of skilled welders. This trend will continue in the future. Automation is therefore the only solution.

- The environmental requirements also become more stringent.

- The need to work more efficient, with a cost reduction as a consequence...