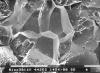

Metallography

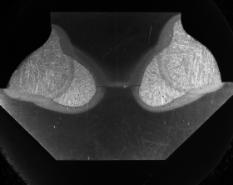

Metallographic section

Metallographic examination plays an important role in the daily activities of BWI, it provides additional elements of information during technical assessment of, for example, a crack indication. Metallografic analysis trought cross-section also proves to be an added value for corrosion investigation, as to identify the depth and level of material deterioration.

BWI is equiped for metallografic examination of all kinds of materials (ferrous- and non-ferrous metals). Stereo, optical and scanning electron microscopes and hardness testers are at our disposal for profound investigations on both small metallographic specimens as on macros:

Microscopes

- stereomicroscope

- optical microscope

- scanning elektron microscope

- microscope with software ‘Olympus Stream’

- profielmeetmicroscoop

Hardness testers

- automatic Vickers hardness tester (HV0,1 to HV10)

- portable Vickers hardness tester (HV10)